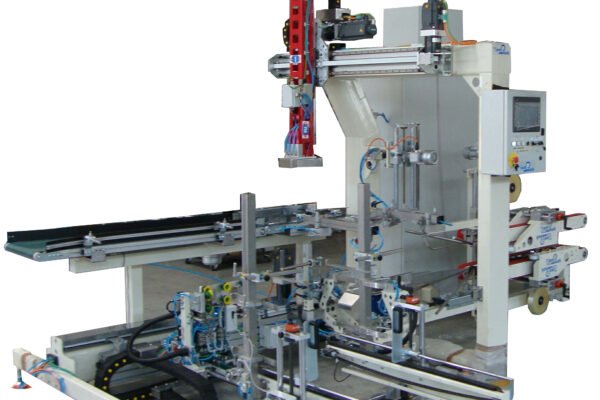

The machine’s vertical loading system inserts products into an American-type carton from a flat blank, including both bottom and top closing.

Introduction

The packaging process is divided into several integrated phases, designed to ensure operational continuity, precision, and a high-quality final result. Each step—from carton forming to product insertion, sealing, and discharge—is handled by dedicated, synchronized modules. This approach optimizes cycle times, reduces errors, and guarantees a reliable package ready for shipment.

Step 1

Pick up from magazine

By means of two servo-driven axes, the carton is formed, the bottom is closed, and the box is positioned under the filling station.

Step 2

Product feeding

The products arrive separated on a motorized infeed conveyor located upstream. They are inserted into the cartons in a predefined quantity. The insertion operation is performed by a dedicated Cartesian-axis handling unit equipped with a specific pick-up head designed to fill one carton at a time. The axis movements are controlled by brushless motors and managed through dedicated software.

(Pick-up tool and infeed module not included)

Step 3

Carton transfer and taping

The carton containing the product is transferred to the next station. During transfer, the flaps are folded by dedicated guides, and adhesive tape is applied for sealing. Hot-melt glue can also be applied as an optional closing system.

Step 4

Discharge of finished carton

The finished carton is transferred toward the outfeed section. An optional control system can be applied to verify the closure of the upper flaps.

Explore the Cartoning Machine INC7

Use the mouse to explore the solution more closely

Technical Specifications

| Package dimensions (L × W × H) |

|

|---|---|

| Closing type | Hot-Melt |

| Output capacity | MC Series: up to 23 packages/minute |

Packaging Solutions

Hooding Machine

Designed for the automatic application of cardboard lids onto display trays.

Introduction

The TRAYCAP MC9 machine is designed for the automatic application of cardboard lids onto display trays, ensuring high precision and productivity. The line is configured to operate at a maximum speed of 9 cycles per minute (to be confirmed according to the specific lid dimensions).

Componenti principali

Blank Feeder Group

• Operation: The blanks are picked up by an asynchronous motor connected to a crank mechanism, ensuring reliable and precise extraction from the magazine.

• Pick-up: A suction-cup arm lifts the blanks and transfers them to the positioning table for subsequent pick-up by the TOOL.

• Features: System designed to guarantee maximum reliability and minimize machine downtime.

Linear Robot Group 1000×1000 mm

• Configuration: Two-axis linear robot with 1000 mm stroke per axis.

• Drive system: Two high-efficiency brushless motors, controlled by advanced electronics for fast and highly accurate positioning.

• Performance: Operating speed up to 23 cycles per minute, ensuring flexibility and high productivity.

• Advantages: Smooth and precise movements optimized for accurate lid application.

Blank Magazine Group

• Structure: Horizontal magazine with pusher and motorized chains for blank support and feeding.

• Adjustment: Independently adjustable sides maintain the perpendicular alignment of blanks during pick-up, ensuring optimal positioning.

• Feeding: Continuous operation even during machine running, offering high autonomy and easy loading.

• Format change: Quick format change through manual handwheels.

• Safety: Equipped with material level and vacuum sensors for constant monitoring and error prevention.

TOOL – Lid Closing Unit

• Function: Positive-motion closing system for folding the lid flaps.

• Quality: Designed to eliminate imperfections caused by scoring or folding, ensuring a flawless and uniform closure.

• Reliability: Robust and precise mechanism optimized for intensive production cycles.

Linepack machines are designed to operate 24/7, ensuring high performance even in the most intense production cycles.

Our machines are designed with compact layouts, thanks also to the electrical panel integrated into the structure.

The format change is designed to ensure speed and simplicity for the operator and minimize downtime.

Manually adjustable magazines as standard, with the option of automatic adjustment for greater operational flexibility.

Option to choose between hot-melt closure or adhesive tape, depending on your specific packaging needs.

Touch screen operator panel with customizable recipes, which can be recalled or modified to quickly adapt to new production needs.

Desideri maggiori informazioni?

Compila il form e invia la tua richiesta. Ti risponderemo entro 24 ore lavorative.